Timber Frame Land Use

As part of the thought experiment post, I want to get a first pass estimate on the land use associated with the building structure and fabric of a timber frame house. I am going to approach this question by first creating a basic model of a 3 bedroom modern long house (inspired by seeing these in Scotland), using a simple stud frame, insulated with wood fibre board insulation. I will then combine the wood quantities that result from the analysis with data on forest yields to work out a land use estimate.

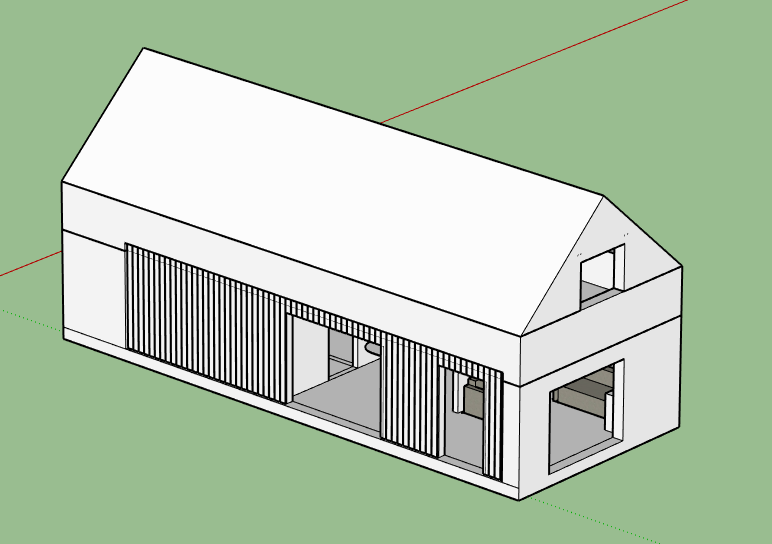

The example house to the left is 13.8m long and 5.6m wide. The internal floor area is 134 m2.

- Roof surface area: 103.6m2

- External wall surface area: 157.2m2

- 1st floor surface area: 67.0m2

- Openings: 24.0m2

- Total surface area: 236.8m2

Without going into full detail on the construction of the house, I will try and get a back of the envelope estimate based on a panel construction of: 2400mm x 1200mm x 12mm OSB, 150mm x 50mm studs at 600mm centers and top and bottom studs.

An example 2.4m x 1.2m panel contains 2x 2.3m long vertical studs (3 studs but half of each side stud is shared with the next panel) and 2x 1.2m long horizontal studs. A total length of 7m. This works out to being 0.01823 m3/m2 of stud timber and 0.012 m3/m2 of OSB.

Mutliplying by the total external wall surface area minus openings results in 2.43 m3 of stud timber and 1.60 m3 of OSB. It's likely that a little more timber would actually be required here given that openings are usually reinforced and that there will be some waste.

Assuming a slightly thicker 250mm thick truss depth for the roof and a roof area of 103.6m2, results in 3.14 m3 of timber and 1.24 m3 of OSB. The first floor is 67.0m2, assuming 250mm thick joists results in 2.04 m3 of timber. 20mm thick floor boards on the upper level: 1.34 m3 of timber and 12mm thick OSB for the 1st floor ceiling: 0.8 m3. 20mm thick external timber cladding would add another 2.66 m3 of timber.

There are about 20m of internal walls (~45m2), at a thickness of 120mm, with 2 sheets of OSB either side and 100mm x 50mm studs results in 0.55 m3 of timber and 0.45m3 of OSB.

Assuming 250mm of insulation throughout would require 236.8m2 x 0.250m = 59.2m3, minus structural timber in the walls and roof 5.6m3 = 53.6 m3 of insulation. This could be provided by woodfibre or cellulose insulation, derived potentially from 'waste' wood resulting from the production of the higher grade sawn wood. The density of wood fibre insulation is about 46 kg/m3, ten times less than solid sitka spruce at 450 kg/m3. We might therefore guess that roughly 5.5 m3 of solid timber would be required for the insulation.

The total so far adds up to 12.2 m3 of sawn timber, 4.1 m3 of OSB and 5.5 m3 of timber waste for woodfibre production, 21.8 m3 overall.

How does this compare with other estimates exploring this question?

The paper The wood from the trees: The use of timber in construction, page 349 and 350 gives an example of a 125m2 apartment at 28.0m3:

The paper gives yield figures for UK and Swedish grown timber:

-

Sitka spruce grown in the UK, an imported conifer from the Pacific Northwest of North America, can yield 14m3/ha.year. This growth rate is higher than those achieved in its native environment due to the UK's milder climate but the resulting density and structural quality is lower.

- Established forests in southern Sweden yield approximately 10 m3/ha.year or 7 m3/ha.year in the first rotation of a newly planted forest.

21.8m3 would require 2.2 to 3.1 ha of forest for one year, or 440m2 to 620m2 over 50 years, if the full tree yield is utilised (Given the potential use of sawn wood waste and low grade wood for both OSB and woodfibre insulation - I would like to come back to this in more detail.)

Looking for a second source for forest yields I came across a Forestry Commission handbook: Forest Yield, A handbook on forest growth and yield tables for British forestry. Suggested Scots pine yields are given at 8.4 - 9.9 m3/ha.year for a stand age of 65 years. Sitka spruce 9.4-10.6 m3/ha.year over 49 years. A particular plot in Brendon, Somerset suggests a yield as high as 15.4 m3/ha.year over 57 years.

Drying

From the paper: "The wood from the trees: The use of timber in construction":

"There are many methods of removing moisture from timber including air, solvent, microwave and supercritical CO2 drying, but the most common in the sawn softwood industry is convective or condensing kiln drying. Convective drying, although energy and equipment intensive, offers the most accelerated means of drying dimensional timber for market"

"One study has shown that the energy required to kiln dry radiata pine can be 3 GJ/m3 specific heat, three times that of easier to dry species like mixed spruce at approximately 1 GJ/m3"

"Studies in the Pacific Northwest of the United States have shown that of all the manufacturing processes associated with converting roundwood into dimensional timber, kiln drying of softwood consumes the most energy accounting for up to 92% of total manufacturing energy."

1 GJ/m3 is equal to 278 kWh/m3. If the 21.8m3 of timber example uses kiln dried wood it would require ~6000 kWh of drying energy. If this heat energy is provided by short rotation coppice with a biomass energy yield of 5.66 kWh/m2/year, it would require 1100 m2 for one year or 21m2 if the building lasts for 50 years and 11m2 if the building lasts 100 years.

Glass

The example house has ~24m2 worth of glazing area. Window glass has a density of ~2600 kg/m3. Assuming tripple glazing and 4mm pane thickness, the total weight of glass would be roughly 750 kg. The embodied energy of glass is about 15MJ/kg or 4.2 kWh/kg, the total energy requirement would be 3150 kWh. If this heat energy was supplied with short rotation coppice, our glass would require 557 m2 for one year. If the glass lasts 25 years before needing replacement, there would need to be 22 m2/household dedicated to glass production.